Girder Pre-Stressing:

The Pioneer posttensioning system proposed, includes a gear range of anchorages, accessories and the necessary equipment to respond to the technical requirements for the construction of bridges and other structures.

The design and calculation of all the components were performed according to the ASTM / BS / European standard, which verification is an obligation in all post tensioning structures built in All Over the World.

Our experience in many fields of post-tensioning applications and our team of engineers and technicians are the guarantee for our success and to face new challenges in the structural engineering field. As application, we are providing posttensioning and cable stayed solutions for any structure as bridges, buildings, tanks of liquefied gas LNG, silos, covertures, communication towers, nuclear power stations, suspended structures, etc.

The services provided by Pioneer include the following aspects:

• Technical assistance in all the phases of the project; from the design to the final execution.

• A large range of live end and dead end anchorages and couplers, being always ready for any development or change according to the specifics needs of the project.

• The designed system was successfully tested according to the ASTM / BS / European standard for posttensioning systems.

• The possibility to use metallic and PE/PP ducts depending on the project specifications.

• Automatic and lightweight stressing equipment.

• Study of alternative design or construction method as an improvement for the optimum solution for every project.

Quality:

Pioneer has developed a complete Quality Assurance Program conforming to ISO 9001:2000 and according to the requirements. Posttensioning, including the design, production, supply and installation of all the required PT works, as anchorages, auxiliary equipment; pushing strands, stressingand injection. By this way, this complete quality system covers all posttensioning work performed by Pioneer.

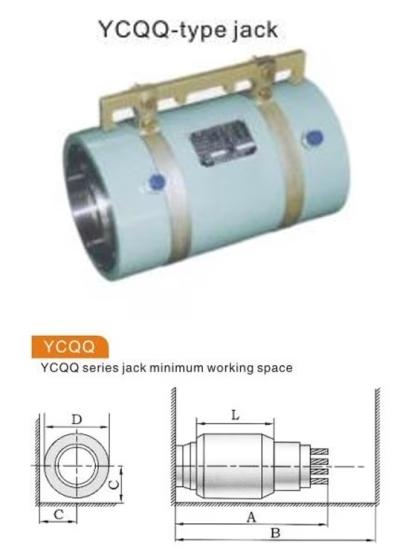

Multi Stressing Jack:

The Pioneer stressing jacks represent the fourth generation in multi stressing equipment.

They incorporate innovative developments including compact design, high

precision and ease of handling.

The Pioneer stressing jacks are essentially center hole moving piston and are designed to work at a pressure of 700 bar.

The jacks internal unit can be rotated thereby facilitating easy alignment with the tendon.

The jacks can be operated in either the standard horizontal position or vertically and features an automatic hydraulic “lock off” device to positively seat the wedges and, thereby, minimize load losses at transfer.

All jacks are calibrated before delivery to site to establish individual force/pressure

Pioneer Mono stressing Jacks. Cassette Series:

The Cassette Jack is primarily designed for the stressing of single strand active anchorages Type MUNB 1/0.6” and Flat Anchorages Type ML. This jack is lightweight (easily manhandable) and incorporates a power lock off to ensure that the wedges are correctly seated inside the barrel, thus preventing the release of the strand under force.

Hydraulic Pumps:

A full range of hydraulic pump equipment and central console units trolley mounted is available.

In addition to the standard hydraulic pump used with all Jacks the new large capacity hydraulic pump is available. This pump is intended to be used in tandem with the larger multi-strand jacks and is capable of operating the largest jack that is currently in production.