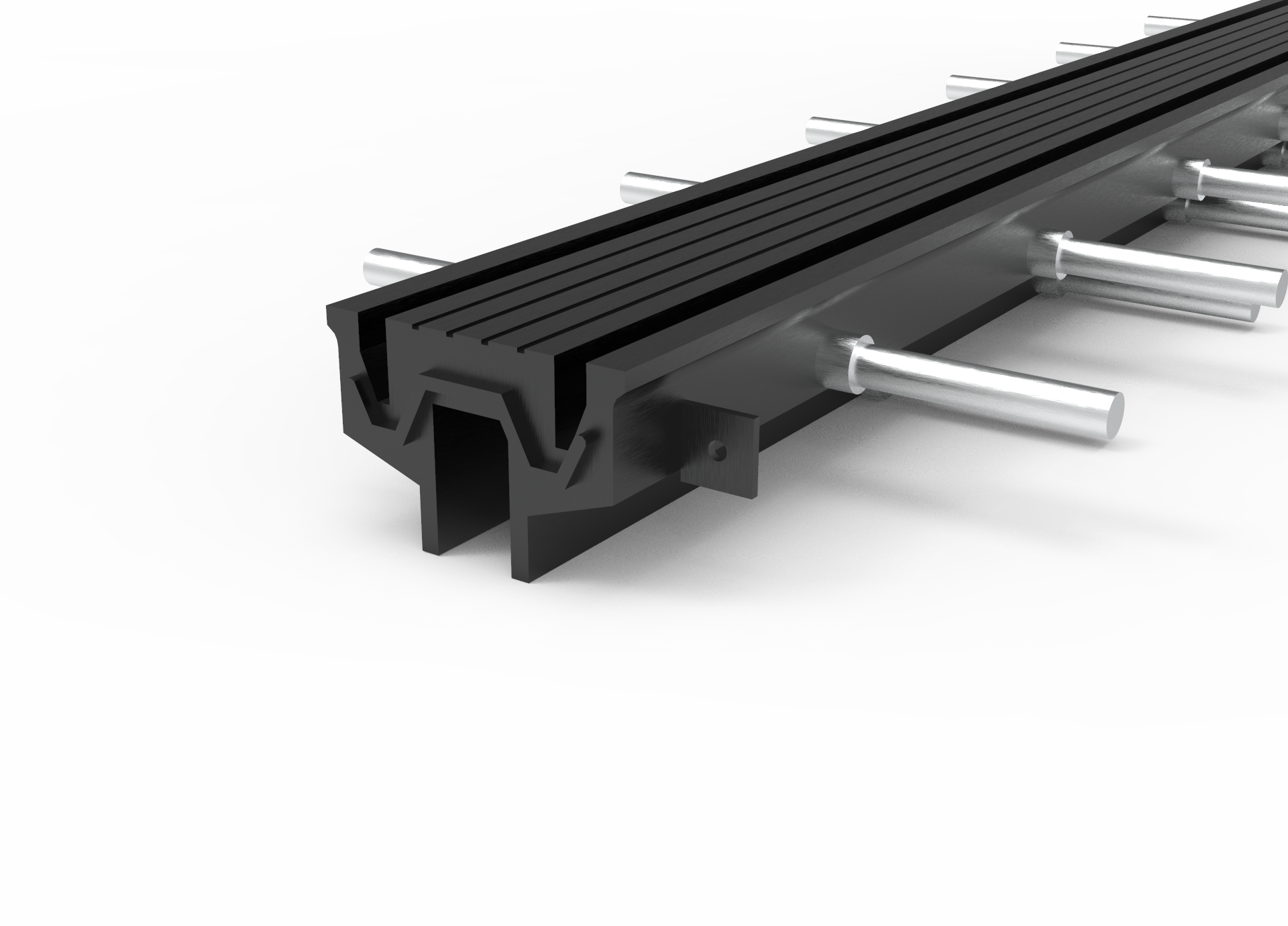

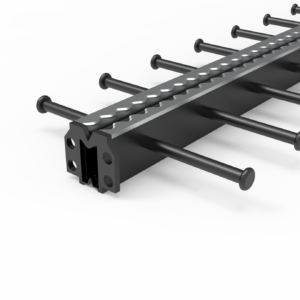

NB Reinforced Rubber Joint:

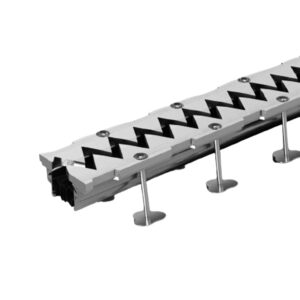

The NB Reinforced Rubber Joint I boasts a robust structural design, ensuring durability through its innovative two-staged bolt-typed anchor system. This configuration effectively transmits loads from passing vehicles on the top plate to the bridge’s supporting components. The narrow top plate, coupled with a thick, rubber-reinforced body, enhances drivability by reducing the vehicle’s contact area and mitigating driving impact.

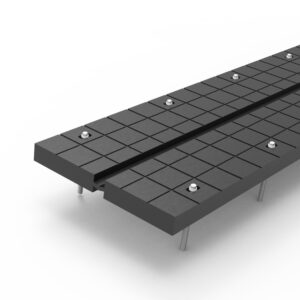

Excellent Drivability:

In addition to structural resilience, the NB Reinforced Rubber Joint I excels in waterproof functionality and aesthetic design. Craft the joints meticulously with a concave-convex shape to maintain a flawless waterproof seal. The lateral reinforced plate is strategically bent upwards during construction to prevent concrete from forming crevices.

Durability:

Addressing environmental concerns, the joint incorporates a Sound Absorption Material (Porous Epispastic) within its structure. This material effectively absorbs noise and shock, contributing to a quieter and smoother driving experience. Furthermore, the joint is designed for long-lasting durability, minimizing potential defect factors and ensuring a prolonged lifespan. Overall, the NB Reinforced Rubber Joint I stands as a testament to its commitment to structural integrity, drivability, water resistance, and noise absorption, making it a reliable and efficient solution for bridge construction.

Reviews

There are no reviews yet.